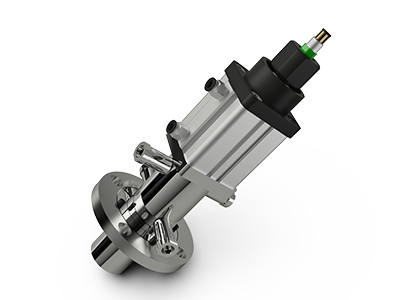

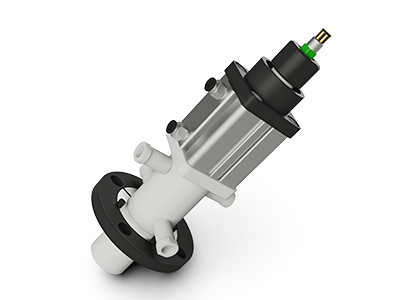

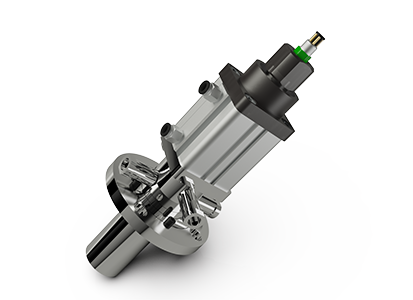

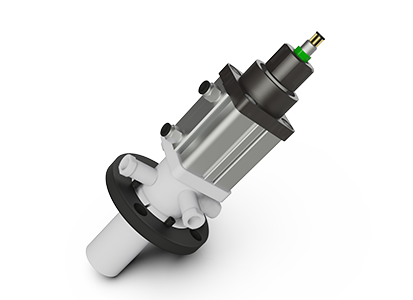

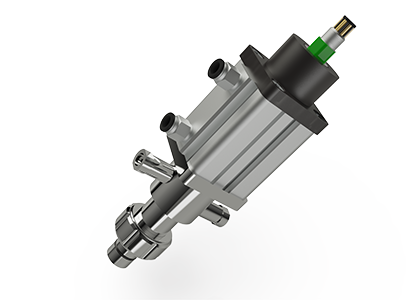

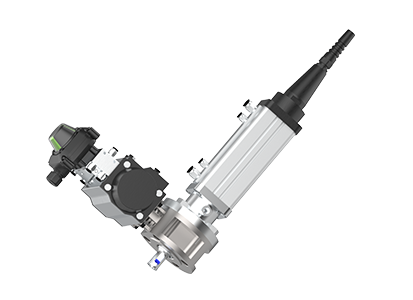

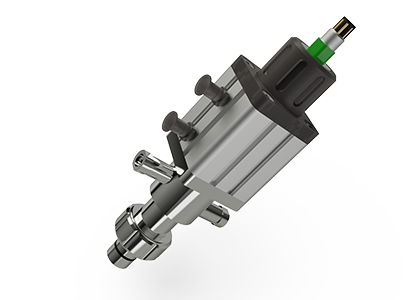

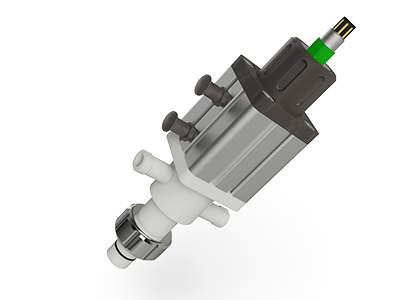

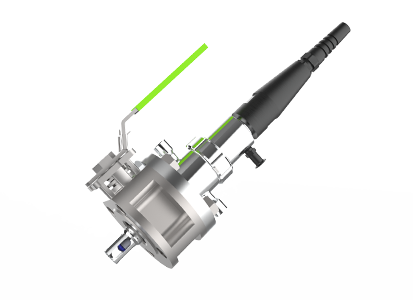

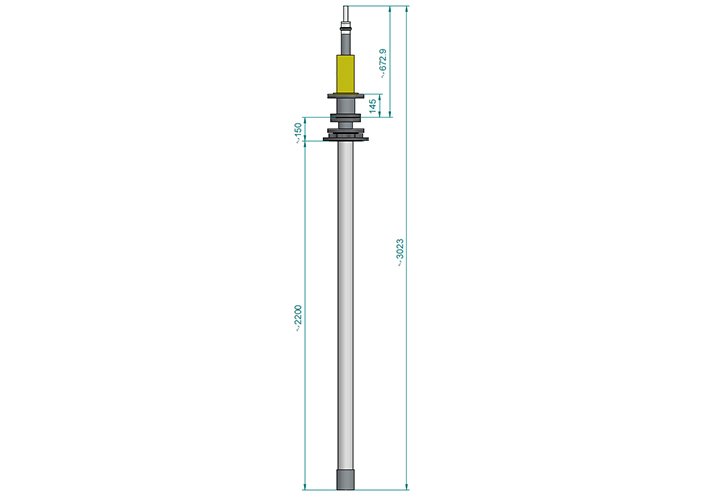

SmartDip TopMount 300M

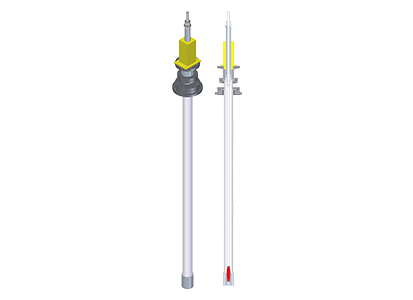

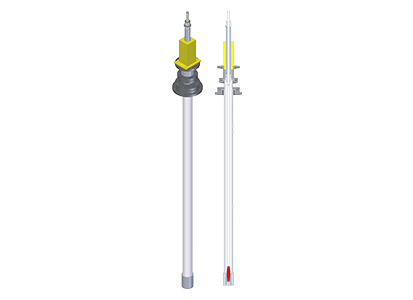

SmartDip TopMount 300M is a retractable electrode housing assembly that can be implemented in chemical vessels and reactors through top flanged nozzles of Jacketed Reactors where side nozzles are not available. This metal or plastic variant assembly is designed like long immersion dip pipes with retractable electrode housing and extended electrode mounting arrangements. It also features an internal flushing arrangement for cleaning and safe keeping of electrode in standby conditions.